| About Us |

| Sai Enterprise is leading manufacturer and supplier of AODD Pumps. Besides, we also offer operational and maintenance services to the clients. Manufactured using quality-tested raw material, our products are highly acclaimed in the market for their longer functional life, robust construction and easy maintenance. These products find wide application in pharmaceuticals, workshops and paper industries. Our firm is facilitated with a sophisticated infrastructure facility, which is outfitted with all the advanced machines and tools required in the production process. This facility is managed and controlled by our dedicated team of professionals. Our professionals apply their extensive industry experience and in-depth experience in precisely manufacturing the products. Owing to their untiring efforts, we have been able to form a broad client-base across the nation. Under the visionary guidance of our skilled mentor, 'Mr. Manish Patel', we have occupied a formidable position in the industry. His constant inspiration, sound business policies and vast industry experience have enabled us to scaled greater heights of success over these years. |

| Product Quality |

| Quality Policy Quality is a passion at Neoflux and the aspects of high quality permeate every department here. The strong process orientation translates into real benefits like reduced cycle times, improved customer satisfaction scores and better cost efficiencies. Neoflux is consistently striving to meet and exceed the tradition of service, quality and integrity by providing the market place with the latest certifications to meet your process needs. Neoflux's management & its employees are deeply committed to excellence, innovation and customer service. |

| Why Us? |

| We have attained an enviable position in the market for providing quality-tested AODD Pumps to the clients. Timely delivery of products have also enabled us in becoming a prominent name in the industry. Transparency and ethics in business is also one of the USP of our organization. |

| Technical Information |

| Why Buy Sai Pumps |

|

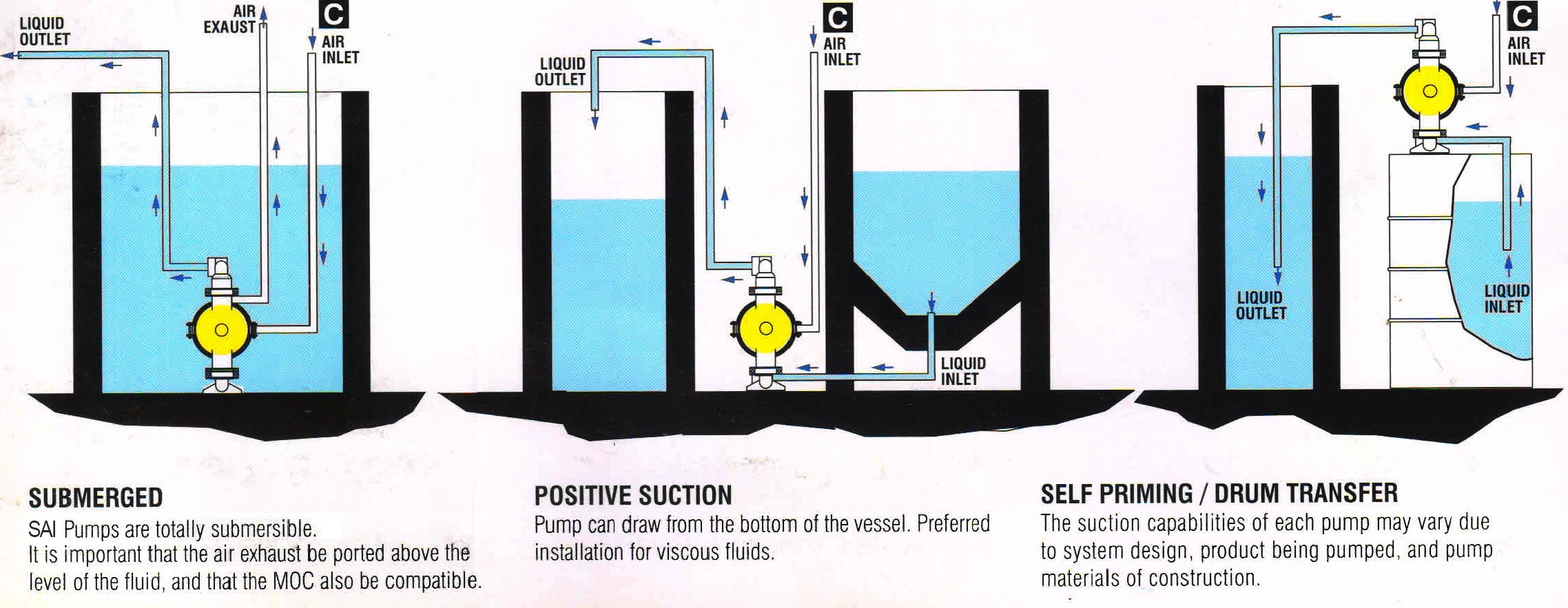

| Installation Versatility |

|

|

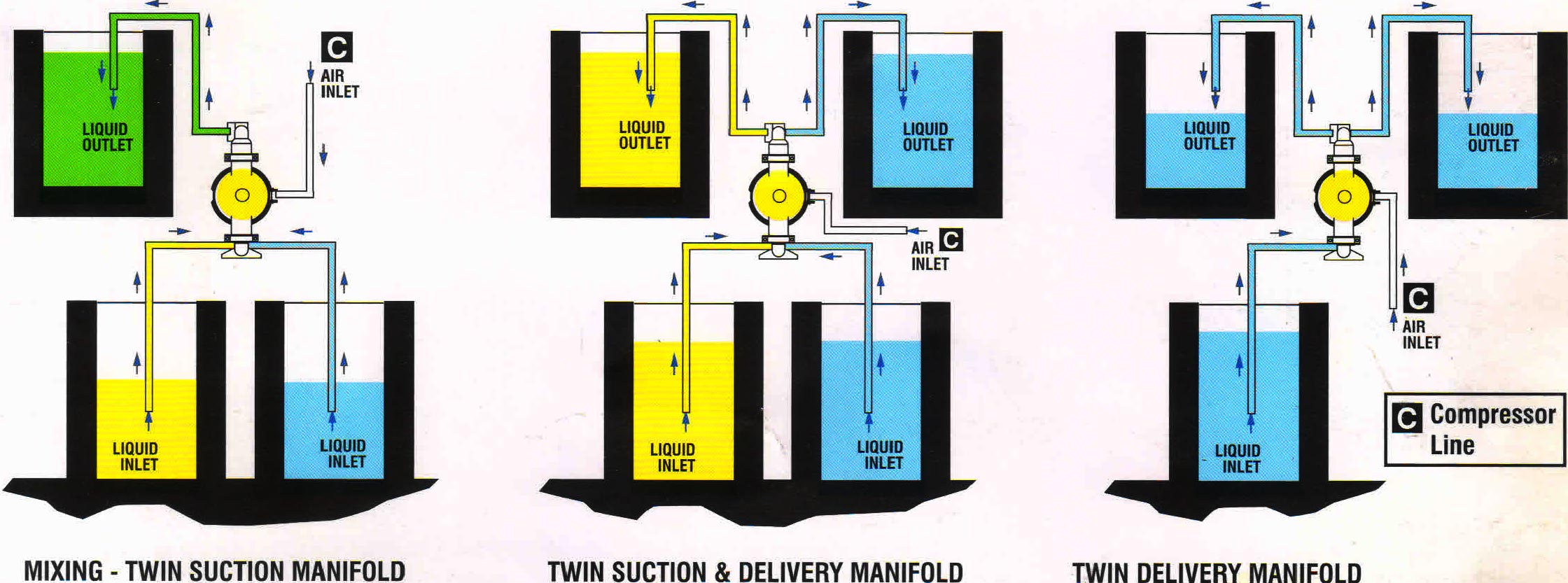

| How The Pump Works |

|

figure 1 left strokeThe air valve directs pressurized air to the back side of diaphragm A. The compressed air is applied directly to the liquid column separated by elastomeric diaphragms. The diaphragm acts as a separation membrane between the compressed air and liquid, balancing the load and removing mechanical stress from the diaphragm. The compressed air moves the diaphragm away from the center block of the pump. The opposite diaphragm is pulled in by the shaft connected to the pressurized diaphragm. Diaphragm B is on its suction stroke; air behind the diaphragm has been forced out to the atmoshere through the exhaust port of the pump. The movement of diaphragm B toward the center block of the pump creates a vacuum within chamber B. Atmosheric pressure forces fluid into the inlet manifold forcing the inlet valve ball off its seat. Liquid is free to move past the inlet valve ball and fill the liquid chamber (see shaded area). figure 2 mid strokeWhen the pressurized diaphragm, diaphragm A, reaches the limit of its discharge stroke, the air valve redirects pressurized air to the back side of diaphragm B. The pressurized air forces diaphragm B away from the center block while pulling diaphragm A to the center block. Diaphragm B is now on its discharge stroke. Diaphragm B forces the inlet valve ball onto its seat due to the hydraulic forces developed in the liquid chamber and manifold of the pump. These same hydraulic forces lift the discharge valve ball off its seat, while the opposite discharge valve ball is forced onto its seat, forcing fluid to flow through the pump discharge. The movement of diaphragm A towrard the center block of the pump creates a vacuum within liquid chamber A. Atmospheric pressure forces fluid into the inlet manifold of the pump. The inlet valve ball is forced off its seat allowing the fluid being pumped to fill the liquid chamber. figure 3 right strokeAt completion of the stroke, the air valve again redirects air to the back side of diaphragm A, Which starts diaphragm B on its exhaust stroke. As the pump reaches its original starting point, each diaphragm has gone through one exhaust and one discharge stroke. This constitutes one complete pumping cycle. The pump may take several cycles to completely prime depending on the conditions of the application. The Sai diaphragm pump is an air-operated, positive displacement, self-priming pump.These drawings show the flow pattern through the pump upon its initial stroke. It is assined the pump has no fluid in it prior to its initial stroke. |